0It is a proven fact that digitization has created inflexion points in markets across world. While PV solar industry is on an unprecedented growth trajectory, solar modules – the most critical and error-prone component of a solar power plant – are yet to be digitized.

Sunsniffer© can digitize your PV modules with patented system and analyze data from each module to automatically calculate module-level loss of power and aid in module replacement decision process. It can’t be simpler! Let the computer do the math and you run the plant keeping the power production and the revenues at the highest level!

The system uses state-of-the art DATA MINING and ARTIFICIAL INTELLIGENCE – wherein each module is fitted with a sensor and the collected data is recorded and analyzed in the cloud based webportal from the time the Modules are assembled in the factory, eliminating the expensive and time consuming processes for identification of the problems during the life cycle of the plant. The data and results are securely accessible from any remote location. This gives comfort in the procurement process by improving the Solar Asset transparency for investors and rating agencies, maximizing the power generation and reducing the O&M Costs besides reducing risks and ensuring safety. With the latest introduction of Sunsniffer© retrofit, this technology can also be applied to existing underperforming plants where the modules are typically warrantied for 25 years.

We can help provide 360 degree service by providing precise module monitoring, sophisticated error analysis, exact service instructions and assure quick performance improvements which can all be monitored from any remote location providing transparency for owners and financiers. All this caution and effort is directed only to ensure quality modules which actually generate the promised power for users to monitor each module performance, identify the changes and their cause with minimal human intervention and take action as recommended to ensure that the plant is always running at optimum levels to maximize the generation and hence the revenue.

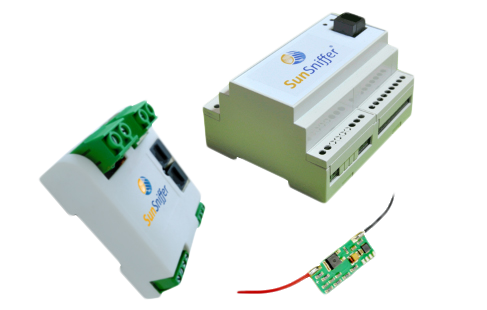

Use of this technology does not require any additional installation nor any additional cables or wiring as the data is transferred over existing DC cabling to cloud portal through string readers and gateway and is accessible over internet from any remote location.

Our innovation is a pioneering technology. It lowers the major cost factors in the operation of a plant – maintenance, error detection and fault finding – and ensures through the continuous real-time monitoring of each module for a constant and optimal energy production and, even, increase. It is much cheaper than so-called “optimizers” and offers far more applications, safety and comfort. There is no comparable technology anywhere in the world. It is protected by patents in numerous countries worldwide and originates in Germany.

Download our brochure here

Do you want us to send you a quote for your plant?

Simply fill the questionnaire and send to us on info@innoway-sea.com!